Posts made by holofloh

-

RE: Emissivity value required!posted in General

this should go as reply to https://community.m5stack.com/topic/1838/ncir-unit-weird-values

accidentally posted as new topic. -

Emissivity value required!posted in General

The NCIR has a MLX90614 sensor on it. https://docs.m5stack.com/en/unit/ncir links the datasheet.

The measurement principe is similar to a thermal camera with just one pixel. It measures the infrared (heat-)radiation that comes from an object. Unfortunately this radiation depends on the surface material where some are good radiators and some are not. To compensate this, the sensor needs to know the emissivity of the measured object.In the datasheet they say: As a standard, the MLX90614 is calibrated for an object emissivity of 1. It can be easily customized by the customer for

any other emissivity in the range 0.1…1.0 without the need of recalibration with a black body.

This means: If your object has an emissivity of 1, then you get correct readings. If your object has for example a emissivity of 0.7 then your reading is wrong as long as you not tell the sensor to calculate with 0.7.Conclusion: To measure with a IR unit (NCIR or a thermal camera) it requires to know the emissivity of the surface. See: https://en.wikipedia.org/wiki/Emissivity for more information and a table of common materials.

-

RE: keyposted in UIFlow

@dingfanshou said in key:

Why can't it connect even though the password is the same?

In the config I see "Start Mode" is "USB Mode". This means, your device is not connecting to WiFi at startup unless a previously stored program does. Change the mode and try again.

-

RE: I2c Geiger Counter for Core-S3posted in General

You may look for something like this: https://www.tindie.com/products/climateguard/dosimeter-with-i2c-radsens-arduino/

-

RE: I2c Geiger Counter for Core-S3posted in General

@rwp908 I do not know any existing. But you can use any Geiger counter kit e.g. equiped with a SBM20 tube or similar that has a pulse output and just use the S3 to count those pulses.

-

RE: how o work with pdm microphoneposted in General

PA Hub is a I2C expander. That means it modifies/replaces the device addresses so it can handle more devices even with the same address. To make this work the software has to decode the "new" address of the device.

PB Hub is a GPIO expander. That means, it simple adds GPIO ports and convert them to one upstream I2C. As with the PA Hub the software has to decode the data.

PDM microphones usually have an output which is electrical close to I2C but still different in the data part (e.g. no addressing). PA Hub is for I2C so it will not work. PB Hub may work if it is fast enough to read the clock and data and decoding the data stream on the Controller. I'm not sure if this is really fast enough.

-

RE: MIDI Synth Unit with DIN & TRS connectors (SAM2695)posted in Modules

When looking to the schematic on the back side of the unit then you will see the signal paths:

- from MIDI IN to Groove TXD and the Switch

- from Grove RXD to SAM2695 and the Switch

- from the Switch to MIDI OUT

Connecting the MIDI IN direct to the SAM2695 is not prepared.

You have to go thru Groove port to do that. It may work if you just bridge the TXD and RXT on the port with a jumper wire (don't forget the 5V supply). Otherwise you have to go thru your processor and put everything what is coming in direct to the out.

-

RE: AIN4-20ma Raspberry Pi Detectionposted in Units

@andrew-winton did you connect the sensor +5V to the +5V and GND to GND of the RPi? Are you sure not having crossed the clock/data pins? I speak from experience... spent more than one hour for a simple failure like this.

When powering on the 5V can you measure if the 3.3V inside the sensor is correct? -

RE: My PC is not recognizing my M5 CARDPUTERposted in M5EZ

@marcelusvictor Did you put the Cardputer into Download Mode as described here? https://docs.m5stack.com/en/core/Cardputer

If Yes, check your device manager if the COM port appears without any error message. If it not apears then your USB cable may be broken or has power wires only (cross check with another one). -

RE: AIN4-20ma Raspberry Pi Detectionposted in Units

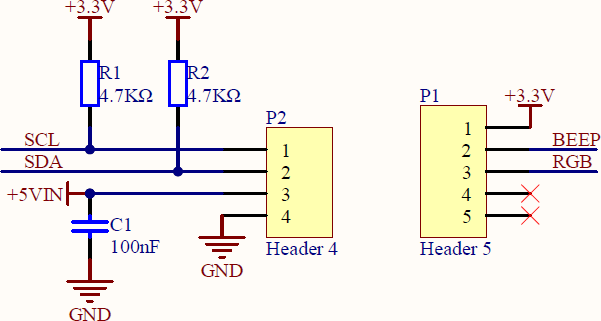

I guess this is a voltage level issue on the power supply for the sensor. M5 Groove Ports use 5V, RPi use 3.3V. Internally the AIN4-20mA use 3.3V (there is a voltage regulator between Groove port and the converter, see the schematic on https://docs.m5stack.com/en/unit/AIN4-20mA Unit) and 5V for the OP-Amp. You may supply the unit with 5V.

-

RE: Add MCP9600 I2C Thermocouple Amplifier - K, J, T, N, S, E, B and R Type Tposted in Features Wish List

@mgrouch KMeter is just the thermocouple converter. The TC insulation itself can be made from plastic or silicon or it can be made from glass fabric. It can also be inside a stainless steel housing or whatever. It depends on the application.

I just did a quick search for exhaust thermosensors and there are many K-type thermocouple in different housing available. As long as they have a TC connector or open wires for mounting one by yourself you can use them with KMeter.I strongly recommend you to read the basics about thermocouples and how they work. You may than understand, that this "plastic thing" can be and should be far away from the high temperature exhaust.

By the way: If you feel better with the MCP9600 then buy one from e.g. Adafruit and use it with its library in the Arduino environment. You controller can still be M5. As for the KMeter the MCP9600 breakout is not made to put in the exhaust as well.

-

RE: Need IR reader and writer with almost any controllerposted in General

@konacurrents You wrote "I'm not using RC-5 with my ESP32 M5 controllers" and in the next posting "eg. the IR doesn't turn the TV on"

So do you want to remote control a TV or another device? If you not using RC-5 what alternative protocol does your device use?For the mentioned test by the mobile phone camera: Test if ANY working remote from TV or HiFi etc... is visible by your mobile phone camera. Point the transmitter to the camera and press a button. If you see a flashing light, then your camera is able to see the IR light.

Now do the same at the M5StickCPlus when one of the examples is running.If there is no flashing IR then investigate on the port number of the IRLED on your device and change it in the code to the right one. If it flashes but your receiving device is not reacting to it, it may be a wrong protocol or command.

It may help if you post the code you are trying and a description of what exactly you want to control.

-

RE: Need IR reader and writer with almost any controllerposted in General

Most IR Remote use RC-5 coding. See https://en.wikipedia.org/wiki/RC-5

Often the IR LED is pulsed with high current on very low duty to increase the working distance (refer the datasheet of your IR LED for maximal pulse ratings). If you have a "normal" IR LED on a GPIO it might be less effective. In this case you have to try very close to the receiver. -

RE: Sending MIDI Signal via USB on M5Dial – Need Help!posted in PRODUCTS

Unfortunately you did not post your code so no one knows how you try to send the midi messages.

Check first: does the device apear as USB-MIDI-Class in your computers device manager?

Probably it is shown as a USB-Serial-Class device (which MIDI indeed is) but your MIDI application (seems to be a top secret application as you don't wrote which one) expect a MIDI-Class device.Maybe this helps: https://github.com/esp32beans/ESP32USBMIDI

-

RE: Vmeter only reads upto 3v and then the ADC value loopsposted in Modules

@erkel

This sounds like a poor solder joint at the internal voltage divider (the 11k and 680k resistors). -

RE: How to use RF Unit RF433T and RF433Rposted in Units

@tspycher

AFAIK: this are very simple transmitter/receiver modules. No protocol, no encryption, no guarantee for transmit/receive the correct data. You have to make your own protocol and data integrity functions.Try to send something out from UART (not faster than 10kbps) and receive it on the other side. Be aware that disturbance could be possible as 433.92MHz is used in a wide range of applications like wireless thermometers, garage door opener, car keys, wireless doorbells, wireless power switches...

As you get the raw pulses out of the receiver it should be possible to receive and decode data from e.g. the thermometer oder switches. There are several protocol descriptions in the web.

If you want to send simple data from one to the other device, ESPnow could be the better option.

-

RE: Can i run M5stack paper while connected to the battery?posted in PRODUCTS

@ScheduleDisplay

Connecting to always ON USB Power will permanent charge your battery and hold it at fully charged level. Not the best state to store a lithium battery over longer time. Best will be to remove it (or at least disconnect). -

RE: UHF-RFID data not visible with other readerposted in Modules

@pete-manzel

As kuriko mentioned before the ID you wrote by M5UHFRFID might be on a different place in the memory (different address) as the sparkfun library try to read it. Are you able to read the raw data and search for your ID?

Anyway, there should also be a read only unique Tag ID (TID) that is given by the manufacturer. Can you get that on both readers?